Aviation Maintenance, Repair, and Overhaul (MRO) is a critical aspect of the aviation industry that ensures the safety, reliability, and performance of aircraft. If you’re curious about exploring the ins and outs of MRO ERP software, you’ve come to the right place. This guide will walk you through the fundamental aspects, processes, and benefits of Aviation MRO, providing you with a well-rounded understanding of their significance.

Introduction

Aviation MRO refers to the various activities and procedures involved in maintaining, repairing, and overhauling aircraft to ensure their airworthiness and longevity. These processes are vital for the safety of passengers, crew members, and cargo, as well as for the overall efficiency and operational success of airlines and aircraft operators.

All That You Need to Know About Aviation MRO

Aviation MRO encompasses a wide range of activities that cover every aspect of an aircraft’s life cycle. From routine inspections to major repairs, each step is designed to meet regulatory standards and ensure optimal aircraft performance. Here’s a detailed overview of the key areas associated with Aviation MRO:

Types of Aviation MRO

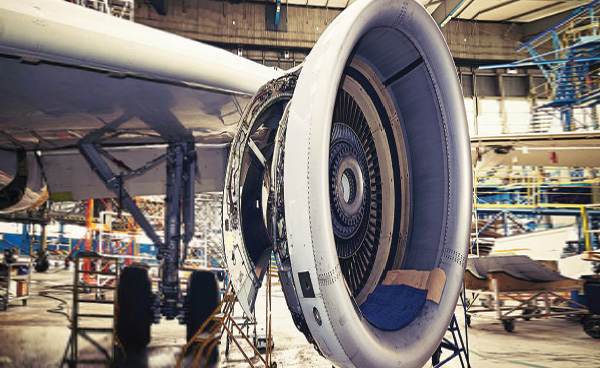

Aviation MRO can be categorized into three main types: Line Maintenance, Base Maintenance, and Component Maintenance. Line Maintenance involves regular checks and minor repairs between flights. Base Maintenance includes more extensive overhauls and inspections, requiring the aircraft to be taken out of service temporarily. Component Maintenance focuses on repairing specific aircraft components, such as engines, landing gear, and avionics systems.

Importance of MRO

The significance of Aviation MRO cannot be overstated. They ensure aircraft safety, compliance with regulations, and optimal performance. MRO activities also contribute to cost savings in the long run by preventing major breakdowns and extending the lifespan of aircraft.

Key Processes Involved

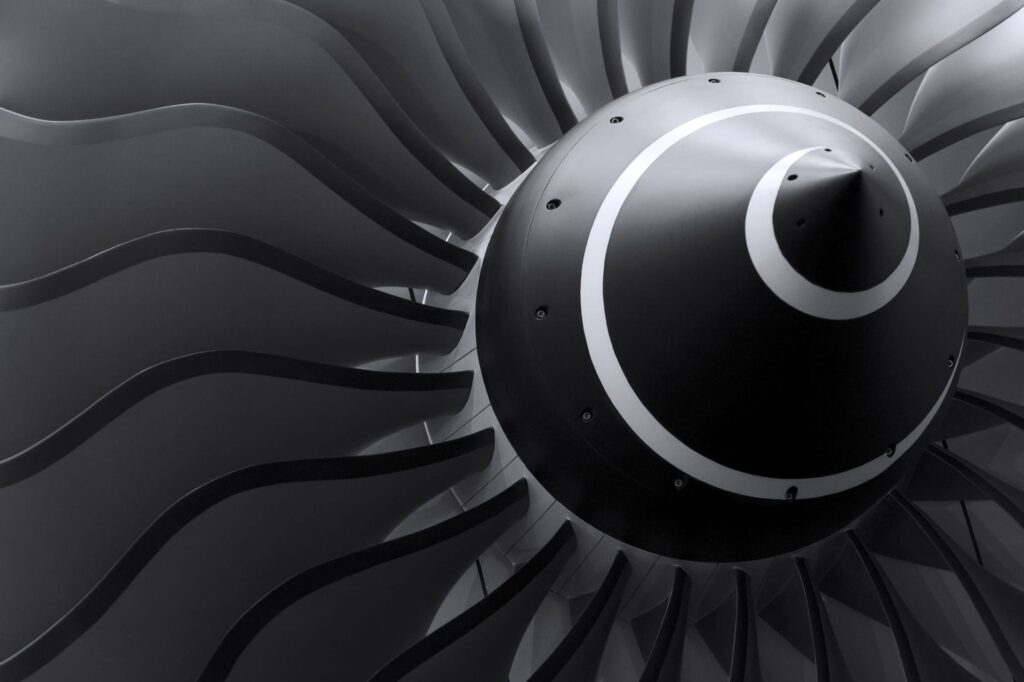

Aviation MRO processes include regular inspections, engine maintenance, air-frame checks, avionics upgrades, and more. These processes are guided by strict regulations and industry standards to guarantee the aircraft’s airworthiness.

Role of Technology

Advancements in technology have revolutionized Aviation MRO. Predictive maintenance, data analytics, and AI-driven solutions enable MRO providers to identify potential issues before they escalate, minimizing downtime and enhancing operational efficiency.

Benefits for Airlines

Efficient Aviation MRO translates to improved flight schedules, enhanced safety, and reduced operational costs for airlines. By adhering to maintenance schedules and promptly addressing issues, airlines can maintain their reputation and ensure customer satisfaction.

Skilled Workforce in MRO

The Aviation MRO industry relies heavily on skilled technicians, engineers, and mechanics. These professionals are trained to handle intricate repairs, complex inspections, and cutting-edge technology, contributing to the overall success of MRO operations.

Regulations and Safety Standards

Strict regulations set by aviation authorities ensure that MRO activities adhere to the highest safety standards. Compliance with these regulations is non-negotiable and is monitored closely to prevent any compromise in aircraft safety.

Sustainability in MRO Practices

Sustainability has become a focal point in Aviation MRO. Airlines and MRO providers are increasingly adopting Eco-friendly practices, such as recycling aircraft components and minimizing waste, to reduce their environmental footprint.

Challenges Faced by MRO Industry

The MRO industry faces challenges such as skilled labor shortages, evolving technology, and the need to balance cost-effectiveness with quality. Overcoming these challenges requires innovation, collaboration, and adaptability.

Outsourcing MRO Services

Many airlines opt to outsource MRO services to specialized providers. Outsourcing allows airlines to focus on their core operations while leveraging the expertise of MRO professionals for maintenance and repairs.

Conclusion

Aviation MRO are the backbone of safe and reliable air travel. By understanding their significance, processes, and benefits, you gain insight into the meticulous efforts that ensure aircraft take to the skies with confidence. From routine maintenance to cutting-edge technology, the world of Aviation MRO continues to evolve, shaping the future of aviation.

FAQs

How often should aircraft undergo maintenance?

Aircraft maintenance schedules vary based on factors like flight hours, cycles, and the type of operation. However, routine checks and inspections occur before and after each flight.

Are MRO activities standardized globally?

Yes, MRO activities are standardized through regulations set by authorities such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA).

Can MRO detect hidden defects?

Yes, MRO use advanced technologies like non-destructive testing to identify hidden defects in aircraft components, ensuring thorough inspections.

What role does data analytics play in MRO?

Data analytics help predict maintenance needs, optimize repair processes, and enhance overall efficiency by analyzing patterns and trends in aircraft performance data.

How do airlines benefit from predictive maintenance?

Predictive maintenance minimizes unscheduled downtime, reduces operational disruptions, and prevents costly breakdowns, ultimately improving flight punctuality and passenger satisfaction.

Is sustainability important in MRO?

Absolutely, sustainability is crucial in MRO. Airlines and MRO providers are adopting Eco-friendly practices to minimize their environmental impact and contribute to a greener aviation industry.